September 2022 Multi-Location Auction

Multi-Locations

Multi-Location Auction Featuring Ribbon Blenders, Centrifuges, Bioreactors, Mixers/Blenders/Tanks, Packaging Equipment, Plastic Extrusion & Ancillary Equipment, Food & Beverage Equipment, Pharmaceutical & Laboratory Equipment, Heat Exchangers, Air Dryers (Unused), Perl Mill, Sifter, and Much More!

Featuring:

Ribbon Blenders

(2) Used - 304 Stainless Steel Double Spiral Ribbon Blenders. Approximate 270 Cubic Foot working capacity. Non-Jacketed trough approximately 144" L x 60" W x 66" Deep. Open top, no cover. Approximate 10" diameter shaft, 1/2" thick x 3" wide outer ribbon, welded to 3-1/2" diameter posts, 7/16" thick x 3" wide inner ribbon welded to 3-1/2" diameter posts. Requires approximate 75hp motor. 20" long x 12" wide Center Bottom Discharge. Mounted on (4) stainless steel legs. 40" discharge height.

(2) Used- 316 Stainless Steel Double Spiral Ribbon Blenders. Approximate 270 Cubic Foot working capacity. Non-Jacketed trough approximately 144" L x 60" W x 66" Deep. Open top, no cover. Approximate 10" diameter shaft, 1/2" thick x 3" wide outer ribbon, welded to 3-1/2" diameter posts, 7/16" thick x 3" wide inner ribbon welded to 3-1/2" diameter posts. Driven by a 75hp 3/60/230/460 volt, 1770rpm motor. Approximate 20" long x 12" wide center bottom discharge. Mounted on (4) stainless steel legs. 40" discharge height.

Centrifuges

Used- Alfa Laval / Sharples PM-3600 Super-D-Canter Centrifuge. 316 Stainless Steel construction (product contact areas), maximum bowl speed 3500 rpm, 4-1/2" single lead conveyor, liquid plate dams, gearbox 125:1 ratio, base, casing, approximate 37kw (49.6hp) main drive motor (380/50/3), back drive moto. Mounted on a carbon steel sub-frame with vibration isolators, safety guards.

Used- Alfa Laval AVNX-426B-31G (same as a PM-36000) Solid Bowl Decanter Centrifuge, 316 Stainless steel construction (product contact areas). 5.5" single lead conveyor with sintered tungsten carbide wear inserts, maximum bowl speed 3250 rpm, 360 degree solids discharge ports, moon liquid plate dams, bowl, P125 gearbox (125:1 ratio), base, casing, lubrication system, 37 kw,(49.6hp) 690/3/50 main drive, back drive, feed pipe with poly addition port, vibration isolators, vibration switch, safety guards, control panel.

(3) Used- Alfa Laval / Sharples P-3400 Super-D-Canter Centrifuges. 316 Stainless steel construction (product contact areas), maximum bowl speed 4000 rpm, 4.25" single lead conveyor w/sintered tungsten carbide wear protection tiles, hogged-out solids discharge ports w/replaceable wear liners, cake flingers, epicentric liquid plate dams, gearbox 52:1 ratio, base, casing, feed pipe, drive motor sub-base, 40 hp drive motor 460/3/60, ECB backdrive w/stand, safety guards.

Used- Alfa Laval Aldec-404 Solid Bowl Decanter Centrifuge. 316 Stainless Steel construction (product contact areas). Maximum bowl speed 4000 rpm, single row of lined cake discharge ports, 110mm single lead conveyor with welded hardfacing, moon liquid plate dams, base, casing, 2.5 KNM gearbox with 159:1 ratio, feed pipe, 22 kw 380/3/50 drive motor, DC backdrive motor.

Used- Flottweg Z53/4-454 OSE Solid Bowl Decanter Centrifuge. 316 Stainless steel construction (product contact areas). Maximum bowl speed 3100 rpm, base, single lead conveyor with cake flingers, lined cake discharge ports, adjustable liquid pans, casing, gearbox, 37 Kw 400/3/50 drive motor, Roto-Diff hydraulic 4 kw back drive with pump and reservoir, lubrication system, feed pipe, safety guards, vibration isolators.

(2) Used- Flottweg Z4D/4-454 Solid Bowl Decanter Centrifuges. 316 Stainless Steel construction (product contact areas), maximum bowl speed 3500 rpm, approximate 5" single lead conveyor with welded hardfacing. Rotodiff backdrive with powerpack, feed pipe, lubrication system, adjustable liquid plate dams, 30 KW (40.2hp) ABB main drive motor with fluid coupling, frame/casing, vibration isolators, safety guards.

(4) Used- Alfa Laval / Sharples SG-15 Super-D-Canter Centrifuges. 316/317 Stainless steel Construction (product contact area), maximum bowl speed 2600 rpm, 360 degree solid discharge ports with sintered tungsten wear inserts, single lead conveyor with sintered tungsten carbide wear protection tiles, P-180 gearbox 95:1 ratio, base, stainless steel casing, 200 hp main drive motor with sub-base, ECB and backdrive stand, lube system, feed pipe, safety guards.

Used- Alfa Laval Aldec-404 Solid Bowl Decanter Centrifuge. 316 Stainless Steel construction (product contact areas). Maximum bowl speed 4000 rpm, single row of lined cake discharge ports, 110mm single lead conveyor with welded hardfacing, moon liquid plate dams, base, casing, 2.5 KNM gearbox with 159:1 ratio, feed pipe, 22 kw 380/3/50 drive motor, DC backdrive motor.

Used- Alfa Laval DSNX-4850 Solid Bowl Decanter Centrifuge. 2205 Stainless steel on product contact areas. Maximum bowl speed 3650 rpm. 2 Phase separation (solids/liquids), single lead conveyor with welded hard facing, 360 degree cake solids discharge ports with replaceable sintered wear inserts, base and casing, missing feed pipe, 10 KNM gearbox with 380:1 ratio, 55kw (73hp), 380/3/50 main drive motor, back drive.

Used- Alfa Laval WSPX-307-71G Desludger Disc Centrifuge. 316 Stainless steel (bowl assembly with aluminum bowl covers). Maximum bowl speed 8375 rpm, concentrator design (liquid/liquid/solids separation), light phase centripetal pump liquid discharge, belt drive configuration, 7.5kw drive motor 380/3/50. Mounted on frame. Rated approximate 22 GPM, sludge space 0.87 gallons.

Used- Alfa Laval / Sharples P-3000 Super-D-Canter Centrifuge. 316 Stainless Steel construction (product contact areas), maximum bowl speed 4000 rpm, 4" double lead conveyor with welded hardfacing,

hogged-out cake discharge ports, liquid plate dams, base, casing, gearbox with torque arm assembly, feed pipe, vibration isolators. Bowl driven by a 29.7hp (22.2 kW), 480/3/60 main drive motor.

Used- GEA Westfalia CTC-1-06-107 Solid Bowl Disc Centrifuge. 316 Stainless steel (product contact areas). Maximum bowl speed 12000 rpm, clarifier design (liquid/solids separation), rated 1.0 kg/cu dm heavy phase, 1.4 kg/cu dm solids, 1 kW motor, centripetal pump liquid discharge, belt drive configuration, bench top design with control panel with VFD motor controller, 120 volt.

(2) Used- Flottweg Solid Bowl Decanter Centrifuges, Model Z32-4/451. 316 Stainless steel (product contact areas). Maximum bowl speed 4500 rpm, 4" double lead conveyor with welded hardfacing, 360 degree cake discharge, ring dam liquid plate, base, casing, feed pipe, 30 kw, 380-660/3/50 belt driven motor.

Used- Flottweg Z5L Solid Bowl Horizontal Decanter Centrifuge. 316/329 Stainless steel construction (product contact areas), maximum bowl speed 2650 rpm, single lead conveyor with welded hardfacing, cyclo gearbox, stainless steel discharge chutes, standard feed pipe, grease lubrication system, adjustable liquid plate dams, fiberglass bowl cover, base, 55 kw, 380/3/50 main drive.

Used- Alfa Laval Solid Bowl Decanter Centrifuge, Model AVNX-616B-31G, 316 stainless steel (product contact areas). Maximum bowl speed 3250 rpm, single lead conveyor with welded hardfacing, moon liquid plate dams, base, casing with cake vibrator, feed pipe, 2.5 Knm gearbox, 11Kw 380/3/50 main motor.

Used- Alfa Laval Solid Bowl Decanter Centrifuge. Model AVNX-420-31G. 316 Stainless steel on product contact parts. 3-1/2" pitch. Maximum bowl speed 4000 rpm. Bowl diameter 8.3/13.8" (210/353 mm). Driven by a 15kw, 3/50/380 volt, 1455 rpm motor. Includes a 2.5 KNM gearbox, top cover, and hydraulic power pack. Serial# 5005201, built 1986. Reported refurbished.

Used- Alfa Laval MMB-304S-11-60 Solid Bowl Disc Centrifuge, bowl assembly construction dupex 2205 and bronze product contact areas, separator design (liquid/liquid/solids separation), maximum bowl speed 9510 rpm, gravity overflow via regulating rings for liquid discharge of the liquid phases, belt drive configuration, 3 hp, 230-460/3/60/3240 rpm AC drive motor, control, mounted on skid with misc piping and pump. Approximate throughput capacities 750 to 3600 LPH.

(3) Used- Sharples P180 Super-D-Canter Centrifuge Gearboxes, 47:1 ratio

Bioreactors

(2) Used- Thermo Scientific Single Use Bioreactors, Model HyClone, 1000 liter capacity, Stainless Steel. Open top, flat bottom shell. 38” diameter x 50” straight side. Dimple Jacket. Includes Brother 3 phase induction motor, 1/2hp 3/60/208-230/460v 1720rpm, 15:1 Ratio. Mounted on Stainless Steel Frame.

Used- Precision Stainless Reactor, 270 Liter capacity, 316L Stainless Steel, Vertical. Approximately 22" diameter x 38" straight side. Dished top and bottom. Internal rated 45psi at -20 to 356 degrees F, 316L stainless steel jacket rated 90psi at -20 to 356 degrees F. Clamp down top cover, openings top: (4) 1-3/4", 4", 4" with sight glass, (2) 3", 2" center bottom outlet, 1-1/2" side bottom outlet. Includes spray

ball. Provision for bottom agitator, missing motor. Side lug mounted. Serial# PJS0010004, National Board# 970, built 2011.

Used- Thermo Scientific Single Use Bioreactor, Model HyClone, 250 liter capacity, Stainless Steel. Open top, flat bottom shell. 24” diameter x 36” straight side. Dimple Jacket. Includes AB Series A Drive, Brother 3 phase induction motor, 1/4hp 3/60/208-230/460v 1720rpm, 12.5:1 Ratio. Mounted on Stainless Steel Frame. Serial# H10289-02.

(2) Used- Precision Stainless Reactors, 60 Liter capacity, 316L Stainless Steel, Vertical. Approximately 16" upper diameter, 8" lower diameter x 18" straight side. Dished top and bottom. Internal rated 45psi at -20 to 356 degrees F, 316L stainless steel jacket rated 90psi at -20 to 356 degrees F. Clamp down top cover, openings top: (4) 3", (4) 1-1/2", 2" center bottom outlet, 1-1/2" side bottom outlet. Includes spray ball. Provision for bottom agitator, missing motor. Side lug mounted. Serial# PJS0010007, National Board# 974, built 2011

Used- Thermo Scientific Single Use Bioreactor, Model HyClone, 50 liter capacity, Stainless Steel. Open top, flat bottom shell. 14” diameter x 22” straight side. Dimple Jacket. Includes AB Series A Drive, Brother 3 phase induction motor, 1/4hp 3/60/208-230/460v 1720rpm, 10:1 Ratio. Mounted on Stainless Steel Frame. Serial# H10289-01.

Used- Paul Mueller Reactor, 25 Liters (6.6 Gallon), 316 Stainless Steel, Vertical. 10" Diameter x 13" straight side. Flat bolt on top, cone bottom. Internal rated 90 psi and Full Vacuum at 32 to 300 degrees F. 304 Stainless steel jacket rated 120 psi at 32 to 300 degrees F. Top openings: (4) 1. 5", (2) 1", 1,25". 3" Center bottom outlet. Mounted on 3 stainless steel legs. Serial# 268418, National Board# 32482. Built 2001.

Mixers, Blenders, and Tanks

Used- Werner & Pfleiderer Mixer Extruder, Type UK80-AES, 316 Stainless Steel on product contact parts. Working capacity 21.2 gallon (80 liter), total capacity 31.7 gallon (120 liter). Double jacketed bowl 20-3/4" front to back x 20-1/4" left to right, approximate 27" deep. Domed top cover with (2) 4" sight glasses, (2) 2", (2) 3/4", suitable for vacuum. Has a grid lid. 316 Stainless steel sigma style blades, approximate 5-1/4" diameter x 44" long 316 stainless steel screw discharge. Blade speed 10.5 to 105 rpm and discharge screw speed 8.5 to 85 rpm. Hydraulic driven by (3) Hydrokraft model PVG130-E hydraulic units driven by 22kW, 50 Hertz motor. Includes (2) control panels, (1) top cover with press piston and ram, (1) extra screw, and misc. parts. Mounted on carbon steel frame.

Used- Lodige Batch Type Plow Mixer, Model FKM600D. 6 Cubic Feet Working Capacity (10 Total), 304 Stainless Steel. Non-jacketed mixing chamber approximate 32" diameter x 50" long. 4" Diameter shaft with (3) bolt on plows and (2) bolt on end scrappers. (2) Approximate 18" x 15-1/2" side access doors. Top openings (2) 12". 9" x 7" Bottom outlet with a manual operated door, air purge seals. Driven by an approximate 10 hp motor thru Falk reducer. Includes a control panel with an Allen-Bradley PanelView 600 and a SLC 5/04 CPU. Mounted on a carbon steel stand. Serial # 9046.

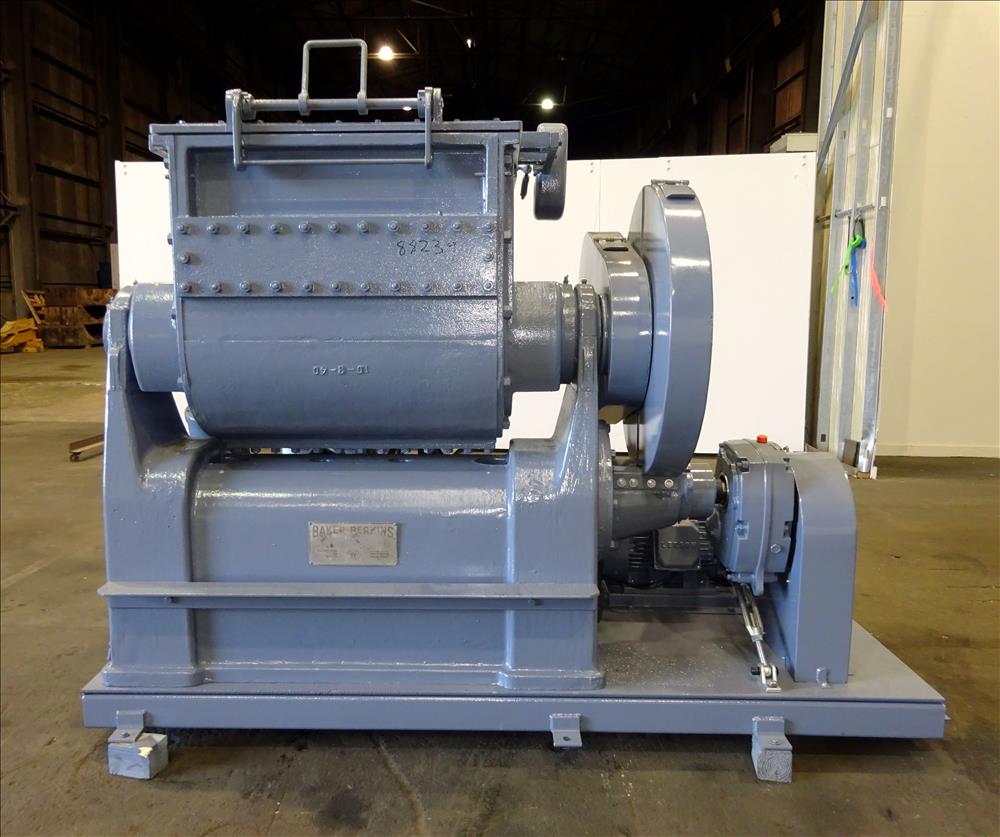

Used/Reconditioned- Baker Perkins Double Arm Sigma Blade Mixer, 100 Gallon Capacity, Model #15. Carbon steel jacketed bowl 33" left-right x 38" front-back x 30" deep. Driven by a 30 hp, 3/60/230/460

volt, 1770 rpm motor with speed reducer. Hydraulic tilt, power pack driven by a 7.5 hp motor. Mounted on a painted carbon steel base. Serial # 41090

Used- Paul O. Abbe Cross Flow Mixer / Twin Shaft Fluidizer, Model AF350, 304 Stainless Steel. 12.4 Cubic feet working capacity, maximum 17 cubic feet. Non-jacketed trough approximately 39-3/8" wide x 49-1/2" long x 35" deep. (2) Approximate 3" diameter shafts with (28) 8" wide x 7" long x 3/16" thick paddles welded with 1-1/4" diameter posts. Bolt on top cover with (2) hinged doors, (2) side access doors. (2) Bombay outlet door, air operated. Driven by a 7.5 hp, 3/60/230-460 volt, 1720 rpm motor with with 24.40:1 gearbox ratio. Mounted on a painted carbon steel frame. Serial# A48097.

Unused- Paul O Abbe Rota Cone Blender, Model RCB-24, 2.4 Cubic Foot Working Capacity, 3.9 Total, Hastelloy C-276. Bulk density 75 pounds a cubic foot, 150 grit internal finish, 22" diameter x 8" straight side x 11-1/2" cone x 12-1/2" cone. Internal rated FV. 8" diameter inlet with cover, 6" diameter outlet with manual butterfly valve. Vessel rotational speed 25 RPM. Internal spray nozzle. Blender driven by a 1/2 HP, 3/60/208-230/460 Volt, 1725 RPM. Includes a Nema 4X control panel. Mounted on a carbon steel base.

Used- AMK Double Arm Mixer, Type VII, Carbon Steel. Approximate working capacity 15 gallon, (29 gallon/112 liter total). Jacketed bowl 20" left to right x 18-3/4" front to back x 15" deep, internal rated -1 bar at 120 degree C, jacket rated 3 bar (43 psi) at 120 degree C. Tangential sigma blades, geared one end, top safety grate, domed top cover with sight glass, suitable for vacuum. Single ram hydraulic tilt with power pack. Mixer driven by a 7.5 kw, 3/50 motor thru a reducer.

Used- American Process Twin Shaft Fluidized Zone Mixer, Model FZM-4S. 4.2 Cubic feet, 120 liters, Carbon Steel. Non-jacketed trough approximate 33" long x 29" wide x 24" deep. (2) 2" diameter shafts each with (14) 5-3/4" wide x 1/8" thick paddles welded to 1" posts. Driven by a 5 hp, 3/60/230/460 volt, 1680 rpm motor. (2) Breaker bars driven by a 1 hp, 3/60/230/460 volt, 1720 rpm motors. (2) approximate 26" x 6" bottom outlets. Has side lugs. Serial# 4388. Built 1995.

Used- Patterson-Kelley Twin Shell Dry Blender, 10 Cubic Feet Capacity, 304 Stainless Steel. Maximum material density 120 pounds per cubic foot. 24" Diameter cones, (2) 18" diameter charge openings with quick release covers. Shell driven by a 2 hp, 3/60/230/460 volt, 1740 rpm motor. Internal pin bar agitator with stainless steel shaft and carbon steel pins, driven by a 2 hp, 3/60/230/460 volt, 1740 rpm motor. 8" Center bottom outlet with a manual butterfly valve. Mounted on carbon steel stands with leg extensions and casters. Serial # 234806.

Used- Tank, Approximately 1,100 Gallon, Stainless Steel. Approximate 60" diameter x 92" straight side, flat top and bottom. (2) 3" Side outlets (threaded). 3" Off center bottom outlet. No manufacturers tag.

Used- Tank, Approximate 1,000 Gallon, Stainless Steel. Approximate 82" diameter x 48" straight side, flat top with bolt on cover. (2) 6", (3) 3" side openings. 3" Off center bottom outlet. No legs. No manufacturers tag.

Used- Stainless Steel Tank, Approximate 400 Gallon, Vertical. Approximate 43" diameter x 64" straight side, dished top, flat bottom. (2) Spray balls, (1) section of internal divider (does not make inside 2 compartments). Openings top (2) 18" manways with covers, (2) 1" tri-clamp, 3" tri-clamp, side 1-1/2" tri-clamp, 3" tri-clamp. 3" Tri-clamp off center bottom outlet, approximate 12" discharge height. Mounted on (4) stainless steel legs.

Packaging Equipment

Unused- Bosch CUT120 Automatic Intermittent Motion Horizontal Tuck Cartoner capable of speeds up to 60 cartons per minute. Has adjustable bucket infeed on 5" centers for a carton size range: length 20 to 113 mm, width 15 to 113 mm, depth 50 to 200 mm. Has a Multifeeder Technology high capacity 16 pocket rotary leaflet feeder, model HCRM125, Multifeeder series MFT250IP friction feeder, and an APL1250 automatic product loader. Cascading pouch transfer system. Has 6' long extended carton magazine, embosse date coder, bar code scanner and verification system. The Bosch CUT120 also has all stainless steel contact points with an aluminum frame. Has automatic pouch transfer and verification system. Has Allen-Bradley Kinet 1x6000 controls and a VersaView 1200P panel. Requires 80 min psi. 3/60/480V.

Used- Merrill Model 72-39 ADH Dual Lane Slat Counter. Machine is capable of speeds up to 300 bottles per minute. Has dual lane vibratory feeder with hopper size of 50-3/4" long x 21-1/2" wide x 22" deep. Equipped with left, right, center, and manifold vibrators, Omron photo eyes, and R50 Blue shockless static neutralizing bar. Includes table top dual lane belt conveyor. Dual lane consisting of 324" long x 4" wide conveyor and 180" long x 4" wide conveyor. Equipped with pneumatic diverter, and single motor for both belts. Conveyor height of 36". Footprint 105" long x 110" wide x 83" tall.

Used- Fuji Formost Model FW3710B Alpha III Activetech Horizontal Box Motion Wrapper. Unit is capable of speeds from 10 to 100 packages per minute. Package size range: 2.25" - 17.5" length; up to 11" width; up to 5" in height. Maximum film width of 23.5", non-registered. Uses Alpha III controls with long dwell seal head, all stainless steel construction, adjustable former and has attach-less infeed with dual flat belt non-flighted infeed system for handling fragile, sticky or difficult to package products. Serial # 093704. 3/60/230.

Used- Hassia Model FVL16/48 Vertical Form FIll & Seal Machine for Liquids and Pastes. Currently set up as a 6-Head Pouch Filler on 2-3/4" centers. Has piston fillers with positive shut off nozzles. Last running a hot fill cheese sauce and ideal for ketchups, mustards, mayonaise or other condiments and sauces. Machine Type: FVL16/48. Machine# 1093000299, Supply Voltage 400~3NPE, with Infeed Funnel, with S/S Discharge Incline Conveyor, with Aprox. 30" W Belt & S/S Frame, with 3-Door Control Panel, with (2) Allen-Bradley PLCs, with 13-Slots & 11 Slots, with Allen-Bradley 1336 Plus VFD, PowerFlex4 & PowerFlex525, with Additional Filler Supply Pump S/S Control

Used- Hayssen Ultimax CM-15 HPR Continuous Motion Washdown Vertical Form Fill Seal Bagger. Capable of speeds up to 130 Bags per Minute (depending on size and application). Suitable for structured, barrier type resistance sealed film, with bagsize range approximately 2" - 15" (width) 2" - 30" (length). Has top and bottom gusseting. Uses Allen Bradley Logix 5561 PLC controls, Allen Bradley Versa View 1200 HMI, Rexroth Servo drives and print registration. Last used in washdown facility and was running frozen sausage and meat products. AEK can mount and integrate fillers per application at an additional cost (combination scales, auger fillers, volumetric cup fillers, liquid/piston fillers etc). 30 amps. 1/60/460V. Currently equipped with a 15" former

Used- Bosch (Syntegon) Model Elematic 3000 Automatic Wraparound Case Packer. Type ELE 3000. Has Nordson Problue hotmelt glue system, Allen Bradley Contrologix 5561 PLC, Allen Bradley Panelview

1000 HMI and Kinetics servo drives. Last running cartons of 1lb and 2lb velveeta cheese brick cartons in a 3 x 4 12 count case. Has right angle infeed with carton up stacker.

Used- Jones Legacy Horizontal Automatic Load Cartoner. Capable of a maximum speed of approximately 400 cartons per minute. Carton size range of 0.75" - 5" length; 0.75" - 3" width (now equipped with 3/4" lugs, 3" lugs are a change part available from oem). 2.5" - 7.25" height. 6" centers. Nordson 3500 Series Glue Unit. Mounted on Casters. 137" long infeed, 6" wide. 43" long carton magazine. Uses Allen Bradley SLC 5/04 PLC controls, PLS 5000 series interface. Emboss Date Coder. Adjustable Bucket Infeed. Indramat Servos. 21.2 amps. 3/60/460V.

Used- Jones Model CMV-5 Semi Automatic Continuous Motion Vertical Cartoner, Model CMV5. Capable of speeds up to 120 containers per minute. Includes Nordson ProBlue 4 hot melt glue unit. Has 5" centers for a carton size range of: Length: 3/4" to 4-1/4"; Width: 1" to 3". Depth/Height 2-1/2" to 8". Lexan safety guarding and stainless steel product guarding. Has 5' long manual load area. Bottom flap embosse date coder, requires print head. Mounted on casters. 3/60/240V.

Used- Fowler Zalkin Model CAS-Twin 3-3/480 Laundry Detergent Capper. Capable of speeds from 8 - 40 bottles per minute. Unit applies pour spout cap and then measuring overcap to plastic containers. Has dual cleated belt cap elevators. Allen Bradley Micrologix Plc controls with Allen Bradely Panel View 1000 HMI. Last running 150 oz laundry detergent containers with 48.5mm diam x 44mm H on turret one and 67.3mm diameter x 70.3mm height on turret number two. 3/60/480v.

Used- IWKA Model SI 6 Horizontal Glue Cartoner. Capable of speeds of up to 60 cartons a minute. Machine is capable of a carton size range of 20-125mm (0.787"-4.92") length; 15-100mm (0.59"-3.93") width; 65-180mm (2.55"-7.086") height. Set up on 6 inch centers. Is equipped with a Ron Tech Model Feeder, GUK Page Folder/Inserter, Nordson Problue 4 Hot Melt Glue System, Laetus Camera Reject System. 3/60/480 volt. Serial #32. Last used in Pharmaceutical Nebulizer Refill cartoning operation from Blow Fill Seal Machine.

Used- Cozzoli VP-12-SF-SS-62 Rotary Vacuum Plugger. Production rate approximate 200 CPM on small fills, 150 CPM on 10 ml containers. Capable of vial diameter size from 2 ml to 100 ml. 12 Head, worm screw infeed. Control panel with Allen Bradley SLC 5/03 PLC controls with A/B panelview 600, Omron drives. Mfg 2008. 3/60/230V.

Used- Anritsu Industrial Solutions Checkweigher, Model KW5366AWND. Capacity 12 to 1200 grams maximum. Maximum speed 220 pieces per minute. Temperature range 0 to 40 degrees C. Serial # 4600137707.

Used- Anritsu Industrial Solutions Checkweigher, Model KW5366AW66. Capacity 12 to 1200 grams maximum. Maximum speed 270 pieces per minute. Temperature range 0 to 40 degrees C. (3) 8" Wide x 13-1/2" long belts. Serial# 4600137706.

Used- PDC Model 65C-ER Automatic Neck Bander / Sleeve Labeler. Rated from 50 to 200 neck bands and 50 to 175 sleeves per minute depending on materials and application. Band / Sleeve size range: 3/8" to 3-1/4" or 10mm - 83mm (diameter) x 5/8" to 8" or 15mm - 200mm (height). Has perforation, print registration, worm screw container indexing. Now tooled for a 70mm lay flat (38mm cap with 42mm od). Allen Bradley Panel View 600 and PLC Allen Bradley 5/04. Plus with PDC Model KRC185254 Shrink Tunnel. PDC Model BDE.

Used- P.E. Labeler Model Master Non-Stop Front and Back Rotary Pressure Sensitive Labeler. 24 stations set up on 4.5" pitch/centers. Uses Allen Bradley SLC 5/04 PLC controls. 3.25" wide x 48" long infeed, 3.25" wide x 87" long discharge. 7" peel plates. 5 Packlab Labeling heads. Was previously running a 1.4" diameter, 4.25" tall deodorant roll bottles. 3/60/480V.

Used- Doboy (Bosch) Model GS1000 XL Paper Bag Sealer. Machine is rated at speeds up to 75 bags per minute. Has a bag width range of 3.5" minimum to 15" maximum. Is capable of sealing 3 to 20 pound bags (larger bags may require modifications) gussetted, multi-wall, and inner liner seal. Has an adjustable height crank for a range of 35" to 79". Uses a Nordson ProBlue 10 hot melt glue unit with one hose and a single head applicator. Uses Direct Logic 06 PLC control system. 25 Amp. 3/60/460V.

(3) Used- Accu-Seal Bag Impulse Sealers, Model 6300-35-B. Seal length 34" maximum x 3/8" width. Has HMI. Mounted on modular frame with casters. 1/60/120 volt, 15amp Power Requirement. Built 2012.

Used- Shanklin Horizontal Side Seal Shrink Wrapper, Model F5B. Capable of speeds up to 75 packages per minute and 90 linear feet per minute. Minimum package size: width 1/2" to 16"; length 3" to 48"; height 1/8" to 6". Has a 9' long flighted infeed conveyor currently set up on 9" centers. Has hot knife end seal film perforating system. Maximum film width 22" folded or 44" flat. Upgraded Allen Bradley Micrologix 1000 PLC with Maple systems HMI. 3/60/208V/230.

Used- Zalkin Model CA3 3 Head Rotary Chuck/Snap Capper. Last running 29mm Bericap (Rical) #7610 closure 7610 on 24 oz, 32 oz and 48 oz round plastic containers of edible / vegetable oil. 3/60/220 v Serial# 23195. Built 1995.

Plastic Extrusion & Ancillary Equipment

Yong Teng 72.5mm Co-Rotating Blocking Parallel Twin Screw Extruder, Model SHJ-75B, Serial# 201411146, Built 2015. With panel.

Xintian Machinery Parallel Twin Screw Extruder, Model SJP75, Serial# 201400074, Built 2014. With panel.

Xintian Machinery 800mm Wide Vacuum Calibration Table, Serial# 201400067, Built 2014.

Xintian Machinery 800mm Wide x 2400mm Long Contact Dual Lane Cleated Belt Haul Off Unit, Serial# 201400068, Built 2014.

JWell Extrusion Machinery Upacting Traveling Cut Off Saw. Cutting range 0-400mm, table approximate 1900mm x 1700mm, with hold-down. Serial# MP1411/174.

Grace-M Plastic Solution Bottom Agitated Stainless Steel Hopper. Approximate 70" diameter x 78" straight side, flat top, bolt on carbon steel flat bottom, approximate overall height 182". Mounted on 4 carbon steel legs.

(3) Grace-M Plastic Solution Stainless Steel Vacuum Loading Hoppers. With mounting frame. Series# 1501001, built 2015.

Grace-M Plastic Solution Stainless Steel Agitated Loading Hopper. With mounting frame.

(2) Stainless Steel Loading Hoppers. With pneumatic sleeve closure and stand.

Lot Consisting Of Miscellaneous valves, connectors, wire, pelletizer head, motor and panel, housing.

Food & Beverage Equipment

Used- BluePrint Automation Robotic Top Loader Robotic Case Packing Line. Case Erector capable of erecting 15 cases per minute with case size range of 10" - 22" length; 6" - 14" width; 9" - 22" height. Robotic Pick and Place unit is capable of moving 100-200 PPM (depending on application). Packer has 4" wide belt infeed product conveyor, 12" wide x 16" long collation section, and now tooled with a 12" x 6" vacuum lift head. Packed cases are discharged to top and bottom case taper. Has Has Allen Bradley SLC 5/04 PLC Controls, and a Panelview 1000 HMI. 30 Amps. 3/60/460V. Last used in IWS sliced stacked cheese pouch packaging operation.

Used- Laudenberg Model PMP20 Duplex Pre-Made Pouch Packager. Capable of speeds up to 80 pouches per minute. Currently set up for 4.5" wide x 7" tall pre-made pouches with zipper and stand-up construction. Has a pouch size range: 80mm - 130mm or 3.15" - 5.12" wide x 120mm - 350mm or 4.72" - 13.87" height. Servo driven turret, has Allen Bradley PLC 5/60 controls and Allen Bradley Panelview 1000 HMI control panel (New PLC/HMI upgrades available upon request). Has duplex powered pouch magazine feed, mechanical/pneumatic pouch and zipper opening station, fill station with funnels on 7" centers, hole punch, seal station and discharge conveyor. Last running tandem zipper stand up pouches of cat pet food treats. Does not include filler. 3/60/480V.

Used- GEI Albro International Scoop Inserter. With scoop elevator and dual vibratory bowl feeders. Last used on 401 diameter can filling line for baby formula filling operation. 3/60/460.

Pharmaceutical & Laboratory Equipment

Used- Dabrico Model Di-200LT Dual Station Vial Inspection System. Capable of inspecting containers at maximums speeds of 150 parts per minute (depending on container dimensions). Line is capable of inspecting 1ml-1000ml vials and syringes, and 1ml-50ml ampoules. Right to Left configuration. With Associated Allen-Bradley PLC Controls. 10 amps. 1/60/120V. Not equipped with any container handling tooling, it is per application, available from OEM. sn 9734

Used- Dabrico Inc. Model DI-100 Vial Inspection System. Capable of inspecting containers at maximums speeds of 150 parts per minute (depending on container dimensions). Line is capable of inspecting 1ml-1000ml vials and syringes, and 1ml-50ml ampoules. Consists of associated counter with dual way conveyor bi-directional accumulation, and a Dabrico Vinyl Inspection Custom 9.5" wide x 76.5" long table top Exit Conveyor. 1/60/120V. Unit requires container handling rollers per application, available from OEM. sn 200615-2/200615-4

Used- Thermo Scientific Laboratory Upright Refrigerator, Model REL5004A23. 20oz charge of R-134A Refrigerant. Approximately 51.1 Cu ft capacity, -58 to -123 Degrees F Temperature Range.

Approximately 52-1/2" wide x 57-1/2" tall x 26" deep chamber, with (4) 25-1/2" deep x 23" wide wire shelves. 115V 60hz power requirements. On Casters. Serial# 0116102301110712

Used- Thermo Revco Upright Refrigerator, Model REL3004A21. 12oz charge of R-134A Refrigerant. 29.2 Cu ft capacity, 1 to 8 Degrees C Temperature Range. Approximately 29" wide x 53" tall x 26" deep chamber, with (3) 29" wide x 26" deep wire shelves. 115V, 60hz power requirements. Serial# P14R-119636-PR

Used- Thermo Scientific Series 2 Water Jacketed C02 Incubator, 184L (6.5 cu. Ft.) Capacity. Inside Glass door, 21-1/2" wide x 27" tall x 19-1/2" deep stainless steel chamber. Temperature range 5C above ambient up to 55C (131F)

Heat Exchangers

Used- Krones Thermowave Plate Heat Exchanger, Approximate 1,534 Square Feet, Type TL 500 FBXV. (10) Chambers each rated 10 bar (145 psi) at 100 degrees C. (212 F.). (307) 254 SMO High-alloy austenitic stainless steel plates approximate 18" wide x 60" tall. Includes (2) spacers, (20) 3-1/4" inlets/outlets. Mounted on an expandable stainless steel frame. Serial# 31891. Built 2008.

(2) Used- Alfa Laval Plate Type Heat Exchangers, Model MX25-BFG. 2906 Square Feet, Vertical. (182) Approximate 24" wide x 85" tall x 0.40mm 304 stainless steel plates rated 150 psi at -20 to 150 degrees F. (2) 8" Inlets, (2) 8" outlets. Mounted on expandable frame with carbon steel end plates. Serial # 30110-65664. National Board # 24801. Built 2006.

Used- Cherry Burrell Thermaflex Plate Heat Exchanger, Approximate 2040 Square Feet, Model 655 STH, 316 Stainless Steel. Approximately (279) 19-1/2" wide x 54" tall 316 stainless steel plates in 2 sections. Hydraulic Closure. Openings (8) 4", (4) 3". Mounted on 304 stainless steel frame. Serial# 91017XA.

UNUSED- WCR Incorporated Plate Heat Exchanger, Model WCR-A891M, 741.1 Square Feet, 316 Stainless Steel, Vertical. (83) Approximate 15" wide x 67" long plates rated hot/cold sides 150 psi at -50 to 266 degrees F. (2) 8" diameter inlet, (2) 8" diameter outlet. Mounted on a expandable frame with carbon steel end plates. Rated 200 - 4000 gpm depending on temperature. National Board # 187. Serial # 1589.15. Year 2008.

Regenerative Air Dryers

(3) Unused in Box. Sullair Regenerative Air Dryer Product Series Desiccant Modular Dryer, Model DMD-40, Sullair Part Number 02250244-035. Vessel Diameter 5", Vessel Height 40", Vessel Thickness 1/3". Purge Exhaust Muffler 3/4". Inlet-Outlet Connection - Inches 1 1/2" NPT; Relief Valve Setting (psi) 200; Bed Velocity (fpm) 60; Sound Max dbA 85; Purge Source Dry Air; Purge Adjust CHECK VALVE; NEMA Cycle (Min) 5 min; Drying time (Min) 2.5 minutes; Regeneration Time (Min) 2 minutes; Repressurization Time (Min) 30 seconds; PERFORMANCE DATA: MAX Ambient Temp (Deg. F/ Deg. C) 122/50; MIN Ambient Temp (Deg. F/ Deg. C) 34 / 1.6 ; MAX Inlet Temp (Deg. F/ Deg. C) 122/50; Max Rated Air Flow at 100 Deg. F (38 Deg. C) ; Inlet, 100 psig (7 barg) and 100 Deg. F (38 Deg. C) Amb 40; Dryer Delta P 2; MIN Pressure (

Purge Rate (at -100 Deg. F) 20%; ELECTRICAL DATA: Standard Voltage 80-240V/ 50-60Hz; Full Load Amps 1; MIN. Circuit Ampacity 2; Input Power kW 0.075; Unit Average kW 0.06; DIMENSIONS & WEIGHT DATA: Single Vessel Desiccant-Lbs 20.9; Ship Weight 164.5; Length-inches 16.1; Width-inches 17.7; Height-inches 49.2; UNIT Weight-lbs 143; Total Desiccant (lbs) 41.8

Perl Mill

Used- Draisewerke Perl Mill, Model DCP-MEGAFLOW ACS-800/PUC, Stainless Steel. Grinding vessel volume net- 62 Liters. Vessel rated 3 Bar (45 PSI) at 70 Degrees C. (158 Degrees F), jacket rated 3 Bar (45 PSI) at 40 Degrees C. (104 Degrees F). Hydraulic chamber raise, and lower with power pack. Double acting mechanical seal. Rotor and bowl are coated. Driven by a 300 HP, 3/60/460 Volt, 1190 RPM motor. Includes a control panel with an ABB drive. Built 2005.

Sifter

Used- Kason In-Line Pneumati-Sifter, Model K60-2PS-CS, Carbon Steel. 60" diameter, single deck, 2 separation. Pneumatic lift dished top cover, bottom separation with coned hopper. Driven by (2) 1.25 hp, 3/60/230/460 volt, 1800 rpm vibratory motors. Mounted on a carbon steel base. Serial # M-5730. Built 2001